Sapphire Watch Case – Complete Guide

I. Overview

A sapphire watch case represents the perfect combination of durability, beauty, and advanced engineering. The global watch industry always seeks innovation, and in this search for excellence, sapphire crystal has become one of the most prestigious materials. Unlike conventional steel or ceramic, sapphire crystal delivers both timeless elegance and unmatched hardness. Consequently, many high-end brands integrate sapphire watch cases into their flagship collections, aiming to impress customers who value exclusivity and technical refinement.

First of all, sapphire has a unique physical identity. It registers a Mohs hardness of 9, second only to diamond. Because of this property, scratches rarely appear on the surface, even after decades of wear. Furthermore, sapphire demonstrates outstanding optical clarity, which allows light to pass through the watch case without distortion. Therefore, a sapphire watch case creates an experience of transparency and brilliance that stainless steel or titanium cannot reproduce.

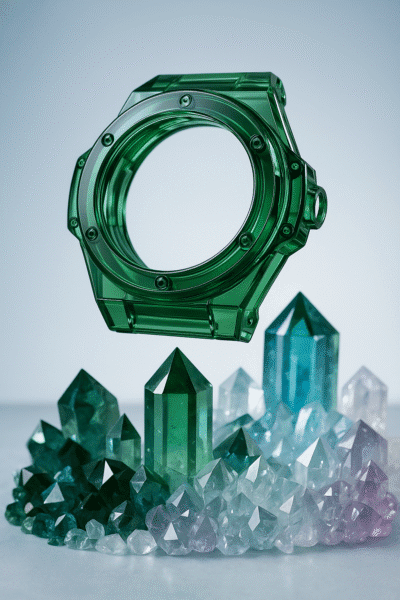

In addition, the visual impact of a sapphire watch case goes beyond clarity. Modern fashion trends highlight individuality and boldness. Transparent, colored, or smoked sapphire provides designers with an opportunity to craft cases that showcase not only the dial but also the movement. Consequently, the case itself becomes part of the art piece rather than a simple protective shell.

On the other hand, a sapphire watch case does not come from a simple process. Behind the glamour exists a long chain of advanced technology, including crystal growth, CNC machining, diamond grinding, and multi-step polishing. Each stage requires high precision, otherwise cracks, inclusions, or irregularities may reduce yield. Only suppliers with extensive experience in sapphire processing can guarantee consistent quality.

Therefore, when evaluating the value of a sapphire watch case, customers should look at both design and craftsmanship. The following sections provide a professional explanation of how sapphire is processed, how polishing creates brilliance, how colors can be customized, and why experience matters in delivering premium products.

II. Sapphire Processing and CNC Diamond Powder Polishing

The journey of a sapphire watch case begins with raw sapphire crystal growth. Synthetic sapphire is produced in large cylindrical boules, often grown by Kyropoulos (KY) or Czochralski (CZ) methods. These techniques create single-crystal structures with uniform optical and mechanical properties. After growth, boules are carefully sliced into blocks, which then undergo further machining.

CNC Machining

CNC technology plays a critical role in shaping sapphire blocks into precise watch case forms. Since sapphire is extremely hard, ordinary tools cannot cut it efficiently. Therefore, manufacturers rely on diamond-coated drills, saws, and grinding wheels. CNC centers allow complex geometries, including transparent lugs, curved profiles, and skeletonized case walls. For instance, the skeleton design of modern sapphire watches would be impossible without multi-axis CNC cutting.

Moreover, precision at this stage determines later success. If tolerance errors occur, polishing will remove too much material, reducing yield. Consequently, only skilled operators can balance cutting speed, tool wear, and surface integrity. In addition, software simulations help engineers plan tool paths that minimize stress and prevent micro-cracks.

Diamond Powder Polishing

After machining, surfaces remain rough and cloudy. To achieve transparency, manufacturers use diamond powder polishing. Because sapphire hardness approaches that of diamond, no other abrasive can polish it effectively.

The process normally begins with coarse diamond slurry, gradually moving to finer grits. Step by step, the surface transforms from matte to glossy. In addition, polishing requires water cooling and controlled pressure, since excessive heat may cause surface burns or stress fractures.

As a result, when the final stage uses sub-micron diamond powder, sapphire achieves mirror-like clarity. Under proper lighting, polished sapphire exhibits crystal transparency that resembles water or ice. Therefore, diamond powder polishing remains the gold standard in the industry.

Challenges in Processing

However, challenges frequently arise. For example, inclusions inside raw sapphire may cause weak points that break during machining. In addition, polishing large curved surfaces evenly requires experience and specialized equipment. Furthermore, the hardness of sapphire accelerates tool wear, increasing cost. Therefore, not every supplier can achieve consistent results.

Because of these factors, a sapphire watch case has a higher price compared to steel or ceramic alternatives. Yet customers accept the premium, since durability, clarity, and exclusivity justify the investment.

III. Color Selection for Sapphire Watch Cases

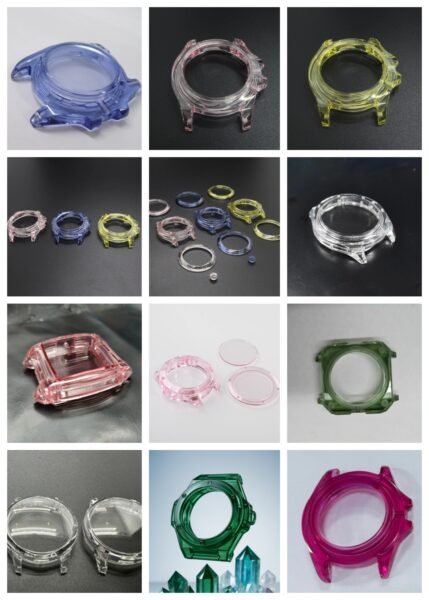

Traditionally, sapphire cases appeared in transparent form. However, modern consumers desire customization and individuality. As a result, manufacturers now offer colored sapphire watch cases.

Transparent Sapphire

Transparent sapphire represents the classic choice. It highlights the movement and emphasizes purity. Many luxury watch brands release limited editions with completely transparent cases, allowing full visibility of tourbillons, skeleton bridges, or rotor systems.

Blue and Green Sapphire

Blue sapphire cases combine elegance with tradition, since natural blue sapphire has been admired for centuries. Moreover, green sapphire provides a modern twist, creating an exotic aesthetic. Both colors are achieved by adding specific dopants during crystal growth.

Red and Pink Sapphire

Red sapphire cases appear bold and energetic. Pink tones appeal to customers seeking elegance with personality. Since these shades require precise control of trace elements, only advanced crystal growers can produce uniform colors without streaks.

Smoked and Gradient Sapphire

In addition, some brands experiment with smoked sapphire, where transparency fades into darker edges. Others combine two colors in a gradient, creating a futuristic style. This innovation increases design possibilities and enhances exclusivity.

Importance of Uniformity

However, achieving uniform coloration across the entire case remains a challenge. Uneven doping may cause streaks or cloudy areas. Therefore, suppliers must carefully monitor growth conditions, temperature, and chemical composition. When color is uniform, the sapphire watch case demonstrates harmony and premium quality.

Consequently, color selection becomes more than an aesthetic choice; it reflects the technical strength of the manufacturer. Customers who request custom colors should confirm whether suppliers have proven experience in controlled sapphire coloration.

IV. Experience and Expertise in Sapphire Watch Case Production

When discussing sapphire watch cases, expertise defines success. Because every stage, from crystal growth to final polishing, requires accuracy, inexperienced suppliers often fail to deliver consistent quality.

Technical Know-How

An experienced manufacturer understands the risks of micro-cracks, the need for gradual grinding, and the importance of stress release. In addition, they optimize CNC programs to balance efficiency and precision. Furthermore, they invest in state-of-the-art polishing machines capable of handling complex curved profiles.

Quality Inspection

Moreover, reliable suppliers establish strict inspection standards. Advanced instruments, such as interferometers and polariscopes, detect internal stress or birefringence. In addition, surface quality is checked under strong light to ensure no scratches remain. Only after passing multiple inspections can a sapphire watch case be accepted.

Customer Collaboration

In addition, experienced teams communicate closely with customers. They provide samples, color swatches, and technical advice. For instance, they may explain that certain case geometries reduce yield and suggest alternative designs. Consequently, customers save time and cost while receiving products that match expectations.

Long-Term Trust

Finally, experience builds trust. A manufacturer with years of sapphire processing history demonstrates stability and reliability. On the other hand, new or inexperienced factories may promise low prices but fail in quality. Therefore, selecting a proven partner remains critical for brands that want to release successful sapphire watch collections.

Conclusion

In conclusion, a sapphire watch case symbolizes the highest level of luxury and precision engineering. From raw crystal growth to CNC machining and diamond powder polishing, every step requires dedication and advanced technology. Furthermore, the availability of multiple colors, including transparent, blue, green, red, and gradient, provides endless design opportunities. Most importantly, only experienced manufacturers can guarantee consistent quality, durability, and elegance.

As a result, customers who choose sapphire watch cases invest not only in a product but also in craftsmanship and prestige. The brilliance, transparency, and exclusivity of sapphire ensure that each watch stands out in the competitive luxury market.