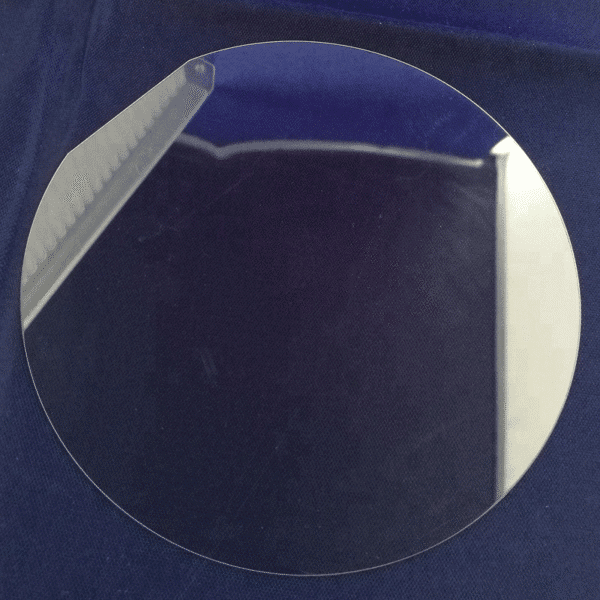

Sapphire Wafer 6 Inch C-Plane – Product Introduction

Overview

A sapphire wafer 6 inch C-plane has become the mainstream size for semiconductor, optoelectronic, and optical industries. Sapphire, chemically known as Al₂O₃, offers outstanding hardness, superb thermal conductivity, and remarkable transparency from ultraviolet to infrared. The C-plane orientation (0001) provides an optimal lattice structure for epitaxial growth of GaN and other III-V compound semiconductors.

Compared with smaller diameters such as 2 inch and 4 inch, the 6 inch sapphire wafer delivers larger surface area, which means higher device output per wafer and reduced cost per chip. As a result, this wafer size dominates modern LED, RFIC, and power device markets. Because global manufacturers want both scalability and reliability, the sapphire wafer 6 inch C-plane stands as the most cost-effective solution for volume production.

Key Advantages of Sapphire Wafer 6 Inch C-Plane

Large Area Efficiency: Higher yield per wafer compared with 4 inch, leading to lower cost per chip.

High Hardness: Mohs hardness 9 ensures durability during processing.

Excellent Optical Properties: Wide transmission from 200 nm (UV) to 5000 nm (IR).

Thermal Conductivity: Handles high thermal load during epitaxy and device operation.

Superior Chemical Stability: Withstands aggressive cleaning and etching environments.

C-plane Orientation: Enables high-quality GaN epitaxy with minimal defect density.

Consistent Flatness: Low TTV, BOW, and WARP ensure process stability.

Because of these properties, the sapphire wafer 6 inch supports mass production and advanced research simultaneously.

Technical Specifications – Sapphire Wafer 6 Inch C-Plane

| Item | Specification |

|---|---|

| Diameter | 6 inch (150 mm ± 0.5 mm) |

| Material | Monocrystalline Al₂O₃ (≥ 99.999%) |

| Crystal Orientation | C-plane (0001) |

| Orientation Accuracy | ±0.3° |

| Thickness | 1300 ± 20 µm |

| Primary Flat (OF) | 47.5 ± 2.5 mm |

| OF Orientation | A-plane (11-20) |

| Surface Type | SSP (Single-Side Polished) / DSP (Double-Side Polished) |

| Surface Roughness | Ra ≤ 0.3 nm (DSP) |

| TTV | ≤ 15 µm |

| BOW | ≤ 20 µm |

| WARP | ≤ 20 µm |

| Edge Profile | Rounded or beveled (custom available) |

| Packaging | Cleanroom wafer cassette, vacuum sealed, shock-proof carton |

Applications of Sapphire Wafer 6 Inch C-Plane

1. LED Industry

The 6 inch sapphire wafer has become the standard substrate for GaN-based blue and white LEDs. The larger surface area enables more chips per wafer, which improves efficiency and reduces production cost.

2. Power Electronics

GaN-on-sapphire devices for RF power amplifiers and high-voltage switches benefit from the thermal stability and lattice match of sapphire substrates.

3. Optical Components

Sapphire’s high transparency and scratch resistance make it ideal for IR windows, UV lenses, and protective covers used in aerospace and defense.

4. Laser Applications

Medical laser systems and industrial cutting lasers use sapphire substrates for durability and resistance to high-power radiation.

5. Consumer Electronics

Smartphones, smartwatches, and wearable devices rely on sapphire wafers for protective glass, camera lenses, and micro-optical components.

Application Summary

A sapphire wafer 6 inch C-plane provides the balance between cost, performance, and scalability. Manufacturers rely on this wafer size for mass production of LEDs, where cost per lumen is critical. Semiconductor companies use it for RFICs and GaN power devices, where high-frequency stability matters. Optical and defense industries value its transparency and mechanical durability, while consumer electronics brands prefer its scratch resistance and premium look.

Because of this broad application range, the sapphire wafer 6 inch C-plane represents the future of substrate technology.

Q&A Section

Q1: Why is the 6 inch sapphire wafer more popular than the 4 inch wafer?

A: Because the 6 inch wafer provides larger usable area, manufacturers can produce more chips per wafer. This reduces cost per device and improves production efficiency.

Q2: Why choose the C-plane orientation?

A: The C-plane (0001) offers the best surface for GaN epitaxial growth. It minimizes lattice mismatch and reduces dislocation density, which improves LED and power device performance.

Q3: Can you provide both SSP and DSP wafers?

A: Yes, both options are available. SSP suits cost-sensitive projects, while DSP ensures ultra-flat surfaces for high-precision epitaxy.

Q4: How do you guarantee wafer quality?

A: Each wafer undergoes strict metrology checks including TTV, BOW, and WARP. All polishing and packaging occur in cleanroom environments to ensure defect-free delivery.

Q5: What is the typical thickness of a 6 inch sapphire wafer?

A: The standard thickness is 1300 ± 20 µm, but custom thicknesses are available upon request.

Q6: Can I order small trial quantities before bulk production?

A: Absolutely. We supply both research-grade small batches and volume-production lots.

Q7: How does sapphire compare with SiC substrates?

A: SiC wafers suit high-power MOSFETs and Schottky diodes, but sapphire wafers remain cost-effective for LEDs and RF devices. Sapphire also provides better optical transmission for IR/UV applications.

Q8: What packaging method do you use?

A: We use wafer cassettes, vacuum sealing, and shock-proof cartons to protect wafers during global shipping.

Conclusion

The sapphire wafer 6 inch C-plane is the cornerstone of modern optoelectronic technology. With its superior hardness, wide optical transmission, and thermal stability, it enables cost-effective mass production of LEDs, RF devices, and optical components. Engineers and manufacturers rely on it for both performance and scalability.

By choosing a sapphire wafer 6 inch C-plane, you secure consistent product quality, higher production efficiency, and reliable supply for demanding industries. Whether your goal is research or high-volume production, this wafer size provides the perfect foundation for advanced devices.